A bottle filling system is a machine or group of machines that are used to fill bottles with a liquid or powdered substance. The system typically includes several components such as a filling machine, a capping machine, a labeling machine, and a conveyor belt to transport the bottles through the system.

There are different types of bottle filling systems available depending on the type of product being filled and the production requirements. Some of the most common types of filling systems include:

- gravity filling, which uses the force of gravity to fill the bottles

- pressure filling, which uses pressurized air or liquid to force the product into the bottles

- volumetric filling, which dispenses a specific volume of product into each bottle

- net weight filling, which fills the bottles to a specific weight

The system can be designed to handle different types of bottles such as glass, plastic, or metal, and different type of product such as liquid, paste, powder, or granules. Modern systems can be integrated with sensors, cameras and other equipment to ensure quality, safety and traceability of the product.

An Arduino-based bottle filling system is a machine or group of machines controlled by an Arduino microcontroller to fill bottles with a liquid or powdered substance. The Arduino can be used to control and monitor the various components of the system, such as the filling machine, capping machine, and conveyor belt, as well as to interface with sensors and other equipment.

To create an Arduino-based bottle filling system, you will need to connect the various components of the system to the Arduino, such as motors and sensors, and then write the software to control them. This software will typically include functions for controlling the movement of the conveyor belt, activating the filling machine, monitoring the level of the product in the bottles, and controlling the capping machine.

There are different ways to design a bottle filling system with an arduino, depending on the complexity of the system, the type of product being filled and the production requirements. Some of the most common methods include using a stepper motor to control the amount of liquid dispensed, using a servo motor to control the capping machine and using sensors such as ultrasonic or infrared to detect the level of the product in the bottles.

Purpose of this project:

In this project, we will build an automatic bottle filling system controlled by the Arduino board.

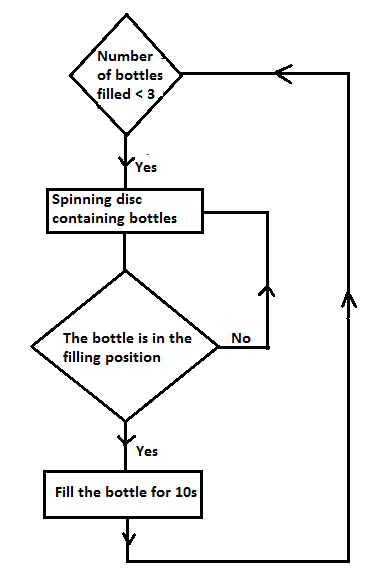

Operation of the bottle filling system

Necessary components

Arduino UNO

The Arduino UNO is a popular open-source microcontroller board based on the ATmega328P microcontroller. It has 14 digital input/output pins, 6 analog inputs, a 16 MHz quartz crystal, a USB connection, and a power jack. It is commonly used for building electronic projects and prototyping, and can be programmed using the Arduino programming language and the Arduino development environment. It is considered as a good starting point for beginners to learn microcontroller programming and electronics.

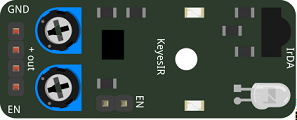

KY-032 sensor

The KY-032 is a infrared reflective sensor module. It is a type of sensor that uses infrared (IR) light to detect the presence or absence of an object. The sensor includes an IR LED and an IR phototransistor. When an object is placed in front of the sensor, the IR light is reflected back to the phototransistor, which generates a signal that can be read by a microcontroller like Arduino. This signal can be used to determine the distance of the object from the sensor or to detect the presence or absence of an object. It can be used for line following and obstacle avoidance in robots and other automation projects.

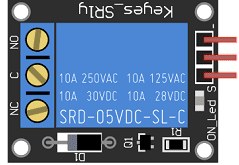

Relay

A relay is an electrical device that controls the power supplied to a water pump. A relay is an electrically operated switch that allows a low power circuit to control a high power circuit.A low power signal from a microcontroller or other control device is used to activate the relay, which in turn supplies power to the water pump. This allows the water pump to be turned on and off remotely or automatically according to a pre-determined schedule. A relay can be used in a variety of applications such as irrigation systems, water treatment systems, and other industrial applications.

US-17H4401 Stepper motor

A stepper motor would likely use a stepper motor to control the precise movement of a filling mechanism, such as a nozzle or valve. This would allow for accurate and repeatable filling of bottles with liquid or other materials. In this specific system, US-17H4401 could be a specific model number of the Stepper motor and the Disc could be part of the filling mechanism which may be used to control the flow of the liquid or other materials. The stepper motor would be responsible for moving the disc in a precise and controlled manner, allowing the system to dispense the exact amount of liquid or material into each bottle.

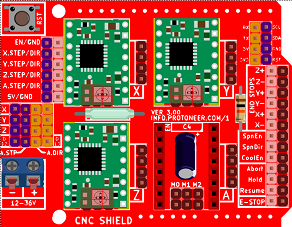

CNC shield

A CNC (Computer Numerical Control) shield is a board that is designed to be used with an Arduino microcontroller to control stepper motors in a CNC machine. It provides a convenient way to connect stepper motors and other devices, such as limit switches and spindle control, to the Arduino.

A CNC shield typically includes several sets of connectors for stepper motor drivers, as well as connectors for other devices, such as limit switches and spindle control. Some CNC shields also include built-in drivers for stepper motors, which can simplify the connection process.

A CNC shield allows you to control the stepper motors with an Arduino board. It uses the Arduino‘s pins to send signals to the stepper motor drivers, which in turn control the stepper motors. By using a CNC shield, you can easily connect stepper motors and other devices to an Arduino and control them using G-code, which is a programming language that is commonly used in CNC machines.

It’s important to note that a CNC shield is not necessary to control a stepper motor with an Arduino, but it can make the process of connecting and controlling stepper motors in a CNC machine much easier and more convenient.

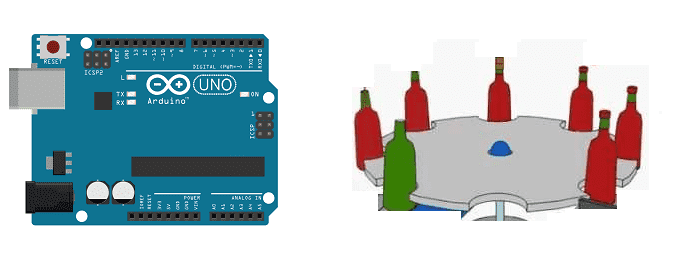

support

In a stepper motor bottle filling system, the disc would likely be supported by mechanical components such as bearings or bushings to allow it to rotate freely. The support structure would also need to securely hold the disc in place and keep it aligned with the other parts of the filling mechanism. Depending on the design of the system, the disc may be supported by a shaft or other rotating element, which would be connected to the stepper motor to allow for precise rotation. The support structure may also include additional components such as seals to prevent leakage of the liquid or other materials being dispensed.

Disc

In a bottle filling system, the disc may be an important component of the mechanism that controls the flow of liquid or other materials into the bottles. It may be used to regulate the flow of liquid by opening or closing a valve, or it may be used to dispense a specific amount of liquid or material into the bottle. The disc may be connected to the stepper motor or other actuator, which would allow for precise movement and control of the disc. The disc could be made of stainless steel, plastic or other materials that are suitable for contact with liquids and easy to clean. The disc could be shaped like a sector and be rotated by stepper motor to control the flow of the liquid or other materials.

timing belt

A timing belt is a mechanical component that is used to transmit power and synchronize the rotation between two shafts. In a stepper motor bottle filling system, a timing belt could be used to connect the stepper motor to the disc, which controls the flow of liquid or other materials in the filling mechanism.

The timing belt would be used to ensure that the disc rotates at the same speed and in the same direction as the stepper motor. This would allow for precise and accurate control of the filling process, as the stepper motor would be able to move the disc in small, precise increments. Timing belt would be chosen based on the specifications of the stepper motor and the disc, such as torque requirements, rotational speed, and operating temperature range.

bottles

12V water pump

A 12V water pump is an electric pump that runs on a 12-volt DC power source and is used to pump water. These pumps are commonly used in a variety of applications such as boats, RVs, and off-grid systems. They are also used in industrial and agricultural settings.

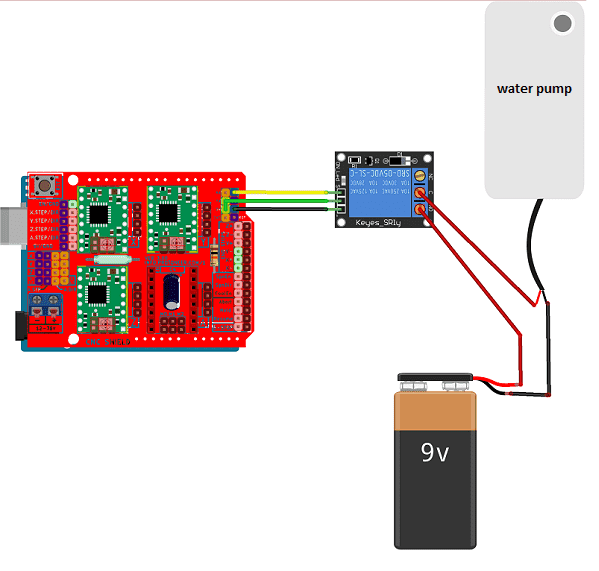

Battery of 9V

A 9V battery is a type of primary cell, or non-rechargeable battery, that is commonly used in a variety of electronic devices such as smoke detectors, remote controls, and portable radios. The standard size for a 9V battery is about 48.5 mm (1.91 inches) in length and 26.5 mm (1.04 inches) in width and 17.5 mm (0.69 inches) in height.

Test plate

A test plate is a type of device that is used to test the functionality of other devices or systems. It can be used to test a variety of different components such as sensors, actuators, and electronic circuits. The design and construction of a test plate will depend on the specific components or systems being tested.

Connecting wires

Wires in a robotic system are used to connect and transmit electrical signals between different components of the robot. These components can include sensors, actuators, motors, and the microcontroller, such as an Arduino. The wires in a robotic system are typically made of copper and are insulated to prevent electrical interference and short circuits.

The type of wires used in a robotic system depends on the specific application and requirements of the robot. For example, a robot that requires high-current power transmission may use thicker, high-gauge wires, while a robot that requires a high degree of flexibility and movement may use thinner, more flexible wires.

Assembly of the Arduino board and the KY-032 infrared sensor sensor

The infrared sensor is used to detect if there is a bottle in the right position to fill it.

-

We connect the (+) pin of the sensor to the 3.3V pin of the Arduino board

-

We connect the GND pin of the sensor to the GND pin of the Arduino board

-

We connect the OUT pin of the sensor to the A4 (SDA) pin of the Arduino board

Assembly of Arduino with the stepper motor

The role of the stepper motor is to turn the disk containing the bottles. We connect the stepper motor to the cnc board which is connected to the Arduino board.

Assembly of Arduino with the water pump

The relay is the intermediate component between the Arduino board and the water pump. It allows the Arduino board to control the water pump.

The role of the relay is to start or stop the pump responsible for filling the bottles.

-

We connect the (-) terminal of the relay to the GND pin of the Arduino board

-

We connect the (+) terminal of the relay to the 3.3V pin of the Arduino board

-

We connect the terminal (S) of the relay to pin A5 (SCL) of the Arduino board

Arduino program

Here is the program that allows you to control the automatic bottle filling system using the Arduino board.

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 |

int analogPin = A4;//the infrared sensor is connected to A4 pin of Arduino int val; int nbr_bouteilles; // for stepper motor configuration const int StepX = 2; const int DirX = 5; int pulseWidthMicros = 1000; // microseconds int millisBtwnSteps = 15000; const int relais_moteur = A5; // teh relay is connected to A5 pin of Arduino void setup() { nbr_bouteilles=1; pinMode(relais_moteur, OUTPUT); pinMode(StepX,OUTPUT); pinMode(DirX,OUTPUT); Serial.begin(9600); } void loop() { if (nbr_bouteilles<=3) { val = analogRead(analogPin); // read the value returned by infrared sensor if ((val < 10)&&(val > 0)) // if the bottle is in the right position { Serial.println(val); nbr_bouteilles++; digitalWrite(relais_moteur, HIGH); // start the water pump delay(9000); // filling for 9 s digitalWrite(relais_moteur, LOW); // stop the water pump translationX(HIGH,LOW,100); // spin the disc } else { translationX(HIGH,LOW,100); // spin the disc } } } void translationX (uint8_t pin1, uint8_t pin2,int stepsPerRev1){ digitalWrite(StepX, pin1); // Enables the motor to move in a particular direction // Makes 200 pulses for making one full cycle rotation for (int i = 0; i < stepsPerRev1; i++) { digitalWrite(StepX, pin1); delayMicroseconds(pulseWidthMicros); digitalWrite(StepX, pin2); delayMicroseconds(millisBtwnSteps); } } |

tracfone coupon 30-11-2222

I love your blog.. very nice colors & theme. Did you create this website yourself or did you hire someone to do it for you? Plz respond as I'm looking to create my own blog and would like to know where u got this from. thanks

tracfone special coupon 2022 29-11-2222

A motivating discussion is worth comment. I do believe that you should write more on this subject, it may not be a taboo matter but generally people do not speak about such topics. To the next! Cheers!!

Milla 05-08-2222

Valuable information. Lucky me I found your site accidentally, and I am shocked why this twist of fate did not came about earlier! I bookmarked it.