A bottle filling system is a machine or set of machines that is used to fill bottles with a liquid or other material. The specific design of a bottle filling system will depend on the type of bottle being filled, the type of liquid or material being dispensed, and the production rate required.

There are several types of bottle filling systems, including:

- Gravity fillers: These use the force of gravity to dispense the liquid or material into the bottle. They are typically used for low viscosity liquids such as water, juice, or beer.

- Pressure fillers: These use a pump or pressurized container to dispense the liquid or material into the bottle. They are typically used for high viscosity liquids such as sauces, syrups, or oils.

- Volumetric fillers: These use a measuring device such as a piston or rotary valve to dispense a specific volume of liquid or material into the bottle. They are typically used for accurate filling of small volume containers.

- Net weight fillers: These use a scale to dispense a specific weight of liquid or material into the bottle. They are typically used for accurate filling of large volume containers.

A bottle filling system can include several different components such as conveyors, filling nozzles, capping machines, labeling machines and packaging machines. The system could be semi-automatic or fully automatic. The system can also include sensors, PLCs, and other electronic devices to control the operation of the system and ensure accuracy and consistency in the filling process.

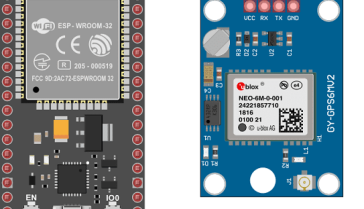

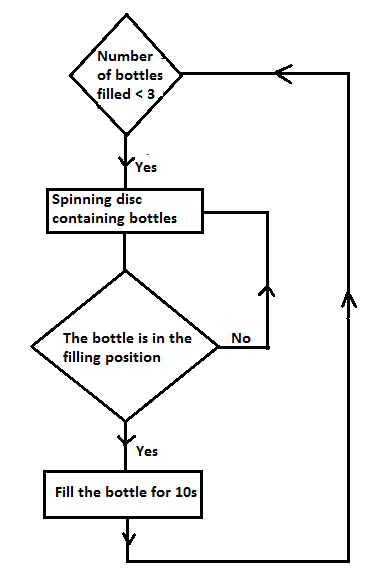

An ESP32 is a microcontroller that is based on the ESP32 microcontroller developed by Espressif Systems. It is a low-cost, low-power system on a chip (SoC) that is designed for wireless communication and has a wide range of features including Wi-Fi, Bluetooth, and a variety of digital and analog inputs/outputs.

An ESP32 can be used in a bottle filling system to control the operation of the system and to communicate with other devices. It can be programmed to control the movement of the bottles on the conveyor, the operation of the filling nozzles, and the capping machines. The ESP32 can also be used to collect data from sensors such as flow meters and level sensors to ensure accurate filling of bottles.

Additionally, the ESP32 can be used to communicate with a central control system, such as a PLC or a computer, to provide data on the status of the filling process and to receive instructions on how to operate the system. The ESP32 can also be used to create a web interface that allows the user to monitor and control the filling process remotely.

Purpose of project:

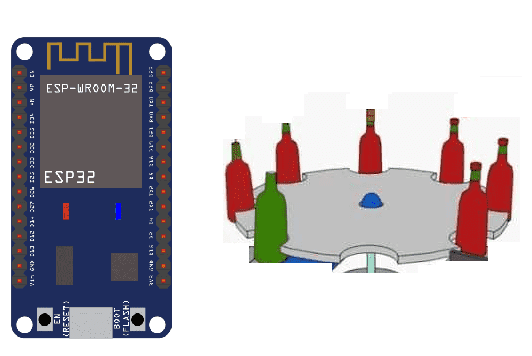

In this project, we will build an automatic bottle filling system controlled by the ESP32 board.

Operation of the bottle filling system

Necessary components

ESP32 card

An ESP32 card is a small, compact circuit board that is based on the ESP32 microcontroller developed by Espressif Systems. It is similar to an ESP32 development board, but it is typically smaller in size and does not have as many peripheral components.

An ESP32 card typically includes the ESP32 microcontroller, flash memory, power supply circuit, and a few digital and analog input/output pins. It can be connected to a computer or other device through a USB interface to program the ESP32 and upload firmware. Some ESP32 cards also include built-in Wi-Fi and Bluetooth, which enables wireless communication and control.

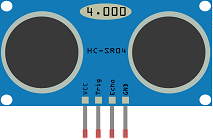

HC-SR04 sensor

The HC-SR04 is an ultrasonic distance sensor. It is a popular and low-cost sensor that is commonly used in a variety of projects such as robotics, automation, and obstacle detection. The sensor works by emitting an ultrasonic sound wave and measuring the time it takes for the sound wave to bounce back to the sensor. The distance to the object can then be calculated based on the time it took for the sound wave to return.

The HC-SR04 ultrasonic distance sensor can be used in a bottle filling system to measure the level of liquid in a bottle or the distance between the filling nozzle and the bottle. This can help to ensure accurate filling of the bottles and to detect any issues with the filling process.

The HC-SR04 in a bottle filling system is to install the sensor at the filling nozzle and program it to measure the distance between the sensor and the bottom of the bottle. This can help to ensure that the nozzle is properly positioned in the bottle before the filling process starts.

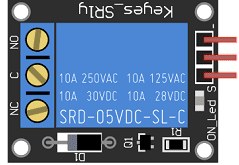

Relay

A relay is an electrical device that controls the power supplied to a water pump. A relay is an electrically operated switch that allows a low power circuit to control a high power circuit.A low power signal from a microcontroller or other control device is used to activate the relay, which in turn supplies power to the water pump. This allows the water pump to be turned on and off remotely or automatically according to a pre-determined schedule. A relay can be used in a variety of applications such as irrigation systems, water treatment systems, and other industrial applications.

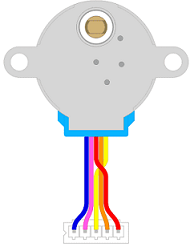

28BYJ-48 stepper motor

A 28BYJ-48 stepper motor would likely use a stepper motor to control the precise movement of a filling mechanism, such as a nozzle or valve. This would allow for accurate and repeatable filling of bottles with liquid or other materials. In this specific system, 28BYJ-48 could be a specific model number of the 28BYJ-48 Stepper motor and the Disc could be part of the filling mechanism which may be used to control the flow of the liquid or other materials. The stepper motor would be responsible for moving the disc in a precise and controlled manner, allowing the system to dispense the exact amount of liquid or material into each bottle.

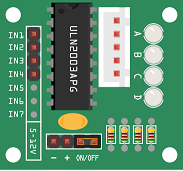

UNL2003 module

The UNL2003 is a type of motor driver module. It is a small, compact device that is used to control the speed and direction of a DC motor. It is based on the UNL2003 integrated circuit, which is a dual H-bridge driver IC. An H-bridge is a circuit configuration that allows a DC motor to be powered in both directions, allowing the motor to rotate in either direction.

support

In a stepper motor bottle filling system, the disc would likely be supported by mechanical components such as bearings or bushings to allow it to rotate freely. The support structure would also need to securely hold the disc in place and keep it aligned with the other parts of the filling mechanism. Depending on the design of the system, the disc may be supported by a shaft or other rotating element, which would be connected to the stepper motor to allow for precise rotation. The support structure may also include additional components such as seals to prevent leakage of the liquid or other materials being dispensed.

Disc

In a bottle filling system, the disc may be an important component of the mechanism that controls the flow of liquid or other materials into the bottles. It may be used to regulate the flow of liquid by opening or closing a valve, or it may be used to dispense a specific amount of liquid or material into the bottle. The disc may be connected to the stepper motor or other actuator, which would allow for precise movement and control of the disc. The disc could be made of stainless steel, plastic or other materials that are suitable for contact with liquids and easy to clean. The disc could be shaped like a sector and be rotated by stepper motor to control the flow of the liquid or other materials.

timing belt

A timing belt is a mechanical component that is used to transmit power and synchronize the rotation between two shafts. In a stepper motor bottle filling system, a timing belt could be used to connect the stepper motor to the disc, which controls the flow of liquid or other materials in the filling mechanism.

The timing belt would be used to ensure that the disc rotates at the same speed and in the same direction as the stepper motor. This would allow for precise and accurate control of the filling process, as the stepper motor would be able to move the disc in small, precise increments. Timing belt would be chosen based on the specifications of the stepper motor and the disc, such as torque requirements, rotational speed, and operating temperature range.

bottles

12V water pump

A 12V water pump is an electric pump that runs on a 12-volt DC power source and is used to pump water. These pumps are commonly used in a variety of applications such as boats, RVs, and off-grid systems. They are also used in industrial and agricultural settings.

Battery of 9V

A 9V battery is a type of primary cell, or non-rechargeable battery, that is commonly used in a variety of electronic devices such as smoke detectors, remote controls, and portable radios. The standard size for a 9V battery is about 48.5 mm (1.91 inches) in length and 26.5 mm (1.04 inches) in width and 17.5 mm (0.69 inches) in height.

Test plate

A test plate is a type of device that is used to test the functionality of other devices or systems. It can be used to test a variety of different components such as sensors, actuators, and electronic circuits. The design and construction of a test plate will depend on the specific components or systems being tested.

Connecting wires

Wires in a robotic system are used to connect and transmit electrical signals between different components of the robot. These components can include sensors, actuators, motors, and the microcontroller, such as an Arduino. The wires in a robotic system are typically made of copper and are insulated to prevent electrical interference and short circuits.

The type of wires used in a robotic system depends on the specific application and requirements of the robot. For example, a robot that requires high-current power transmission may use thicker, high-gauge wires, while a robot that requires a high degree of flexibility and movement may use thinner, more flexible wires.

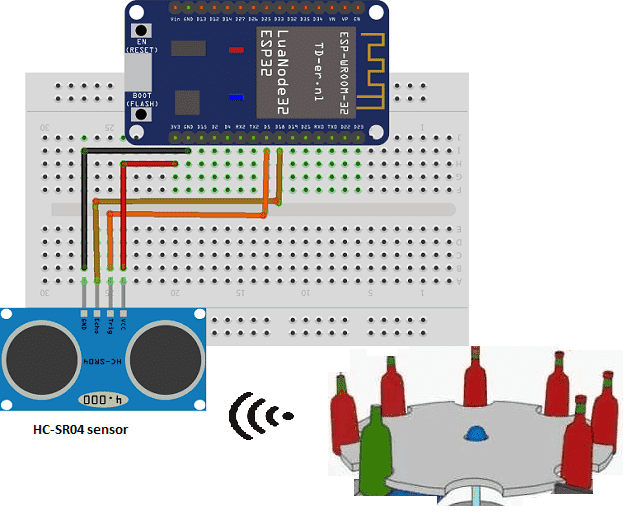

Mounting the ESP32 board and the HC-SR04 sensor

The HC-SR04 sensor is used to detect if there is a bottle in the right position to fill it.

-

We connect the VCC pin of the sensor to the 3.3V pin of the ESP32 board

-

We connect the GND pin of the sensor to the GND pin of the ESP32 board

-

We connect the Trig pin of the sensor to pin N°5 of the ESP32 card

-

We connect the Echo pin of the sensor to pin N°18 of the ESP32 board

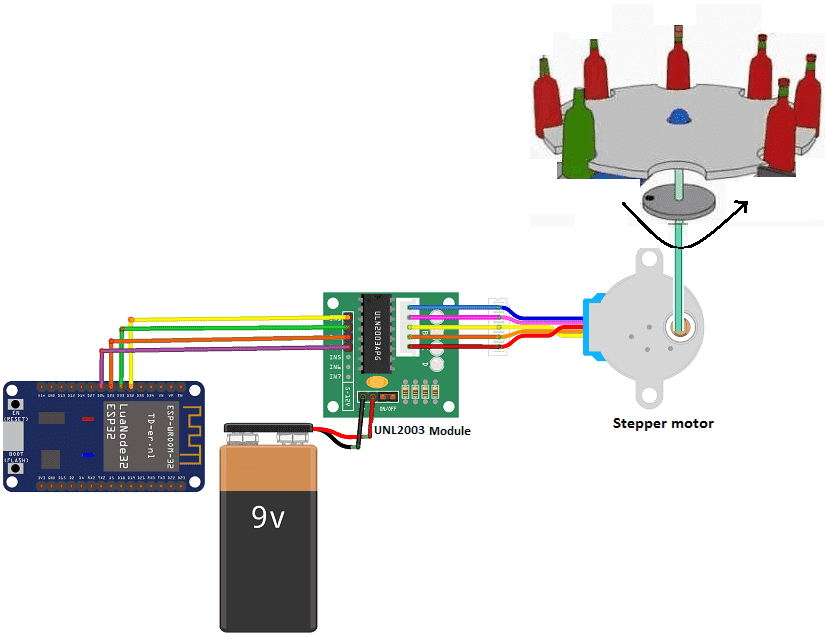

Mounting the ESP32 board with the stepper motor

The role of the stepper motor is to turn the disc containing the bottles

-

We connect the UNL2003 module to the stepper motor

-

We connect the IN1 pin of the UNL2003 module to pin N°32 of the ESP32 card

-

We connect the IN2 pin of the UNL2003 module to pin N°33 of the ESP32 card

-

We connect the IN3 pin of the UNL2003 module to pin N°25 of the ESP32 card

-

We connect the IN4 pin of the UNL2003 module to pin N°26 of the ESP32 card

Mounting the ESP32 board with the water pump

The relay is the intermediate component between the ESP32 board and the water pump. It allows the ESP32 board to control the water pump

The role of the relay is to start or stop the pump responsible for filling the bottles.

-

We connect the (-) terminal of the relay to the GND pin of the ESP32 board

-

We connect the (+) terminal of the relay to the 3.3V pin of the ESP32 board

-

We connect the terminal (S) of the relay to pin No. 19 of the ESP32 board

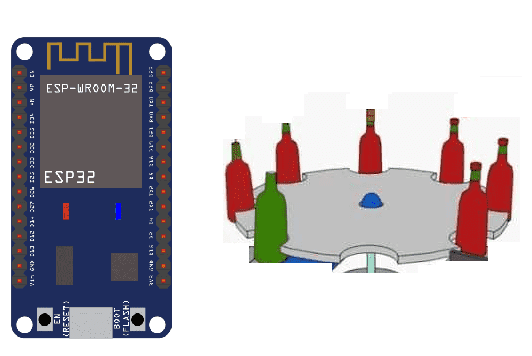

Micropython program

Here is the micropython program which allows to control the automatic bottle filling system by the ESP32 card.

You have to use these two libraries: Stepper.py et hcsr04.py

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 |

import Stepper from machine import Pin, ADC import time from hcsr04 import HCSR04 # for the ESP8266 # In1 = Pin(2,Pin.OUT) # IN1-> GPIO2 # In2 = Pin(0,Pin.OUT) # IN1-> GPIO0 # In3 = Pin(4,Pin.OUT) # IN1-> GPIO4 # In4 = Pin(5,Pin.OUT) # IN1-> GPIO5 # for ESP32 In1 = Pin(32,Pin.OUT) In2 = Pin(33,Pin.OUT) In3 = Pin(25,Pin.OUT) In4 = Pin(26,Pin.OUT) pompe=Pin(19,Pin.OUT) sensor = HCSR04(trigger_pin=5,echo_pin=18,echo_timeout_us=1000000) nbr_bouteilles=1 s1 = Stepper.create(In1,In2,In3,In4, delay=1) time.sleep(5) while (nbr_bouteilles<=3): distance = sensor.distance_cm() print(distance) if (distance<1000): # if the hc-sr04 sensor detects the bottle being in the correct position nbr_bouteilles=nbr_bouteilles+1 s1.step(0) # stop the stepper motor pompe.value(1) # start the water pump time.sleep(10) # fill the bottle for 10s pompe.value(0) # stop the water pump s1.step(200) # spin the disc containing the bottle else: s1.step(50) # spin the disc containing the bottle s1.step(150) |